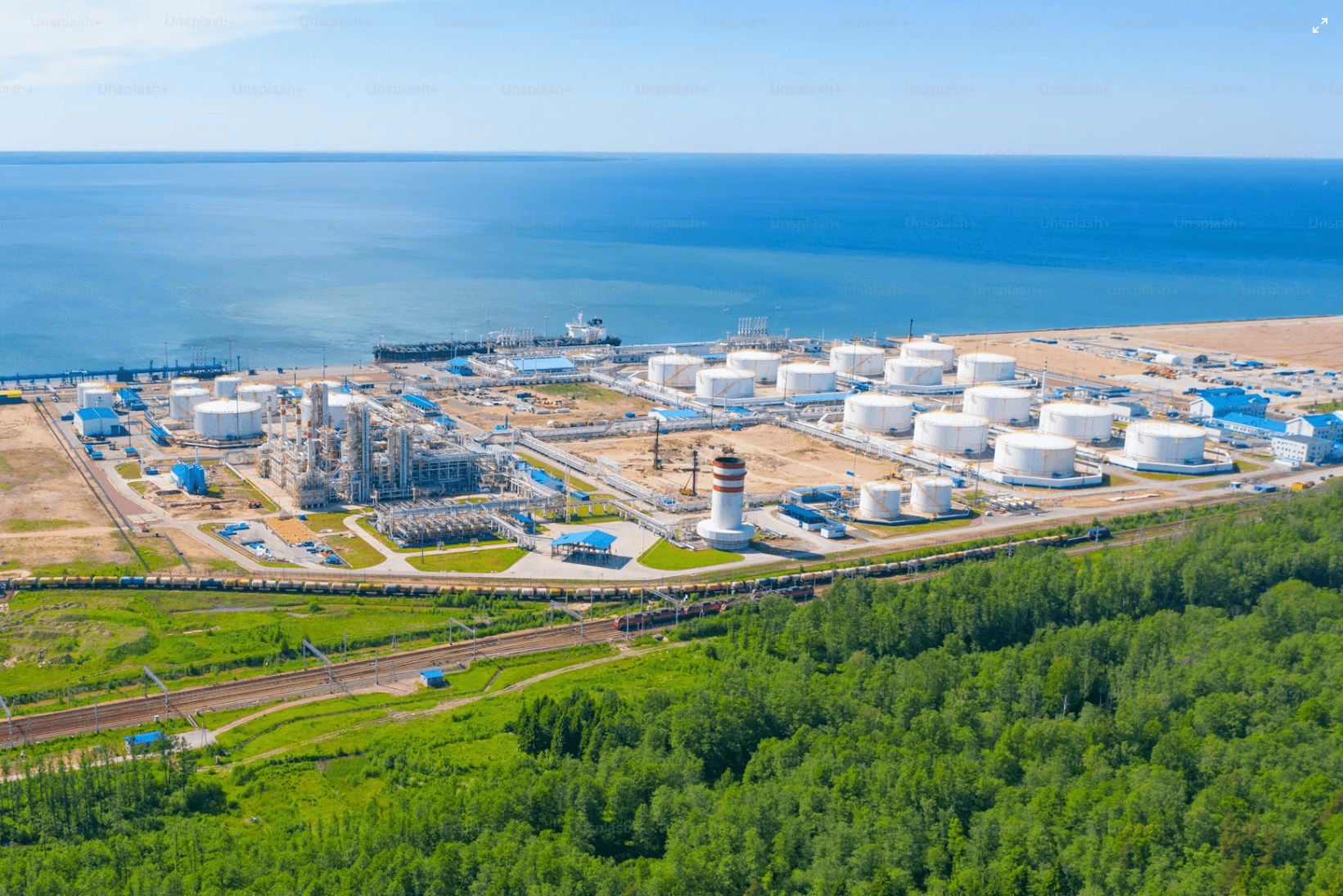

Our Market Solutions

A scalable, low-emission process that delivers reliable fuel quality, long-term environmental benefits, and durable economic performance.

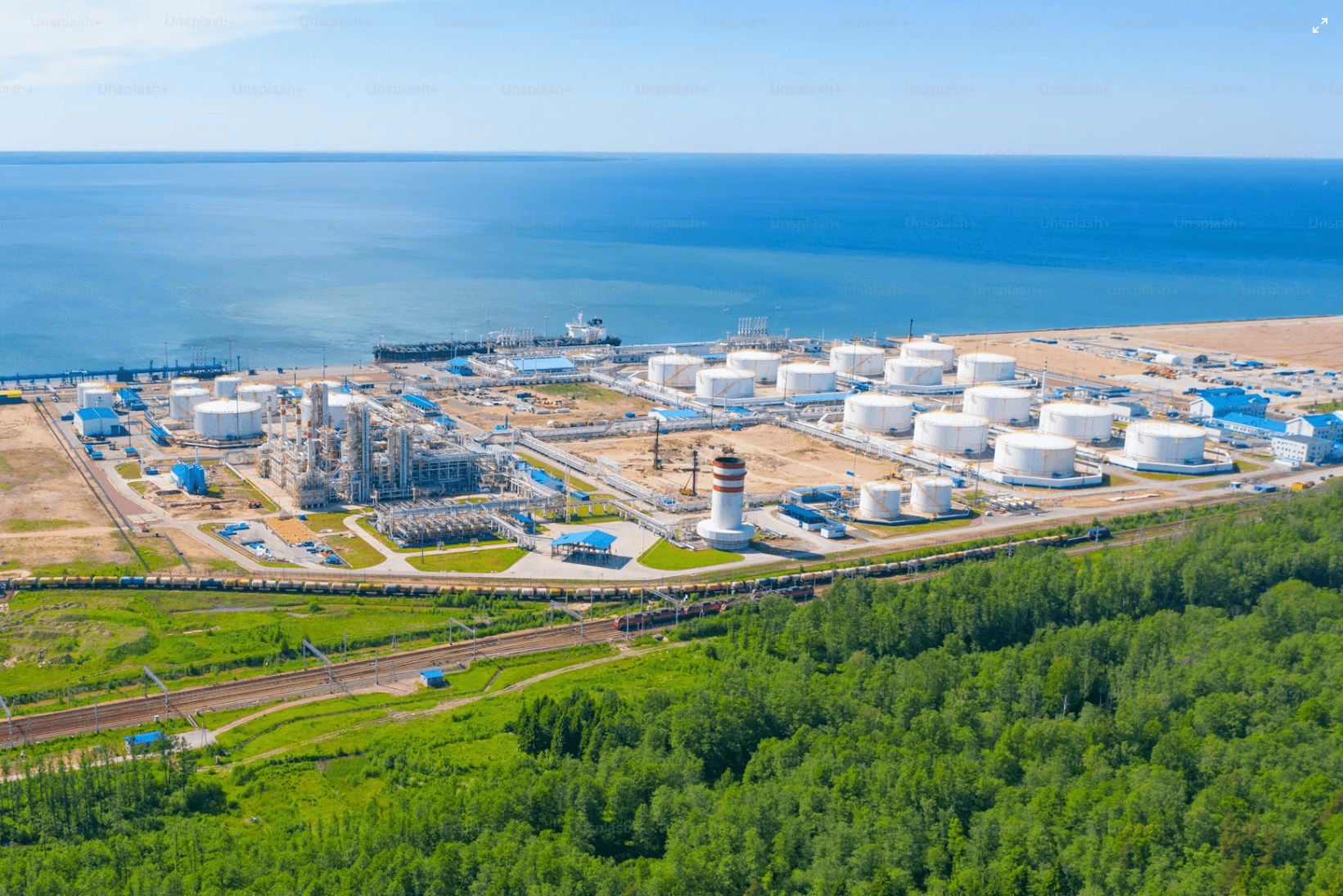

Our Market Solutions

A scalable, low-emission process that delivers reliable fuel quality, long-term environmental benefits, and durable economic performance.

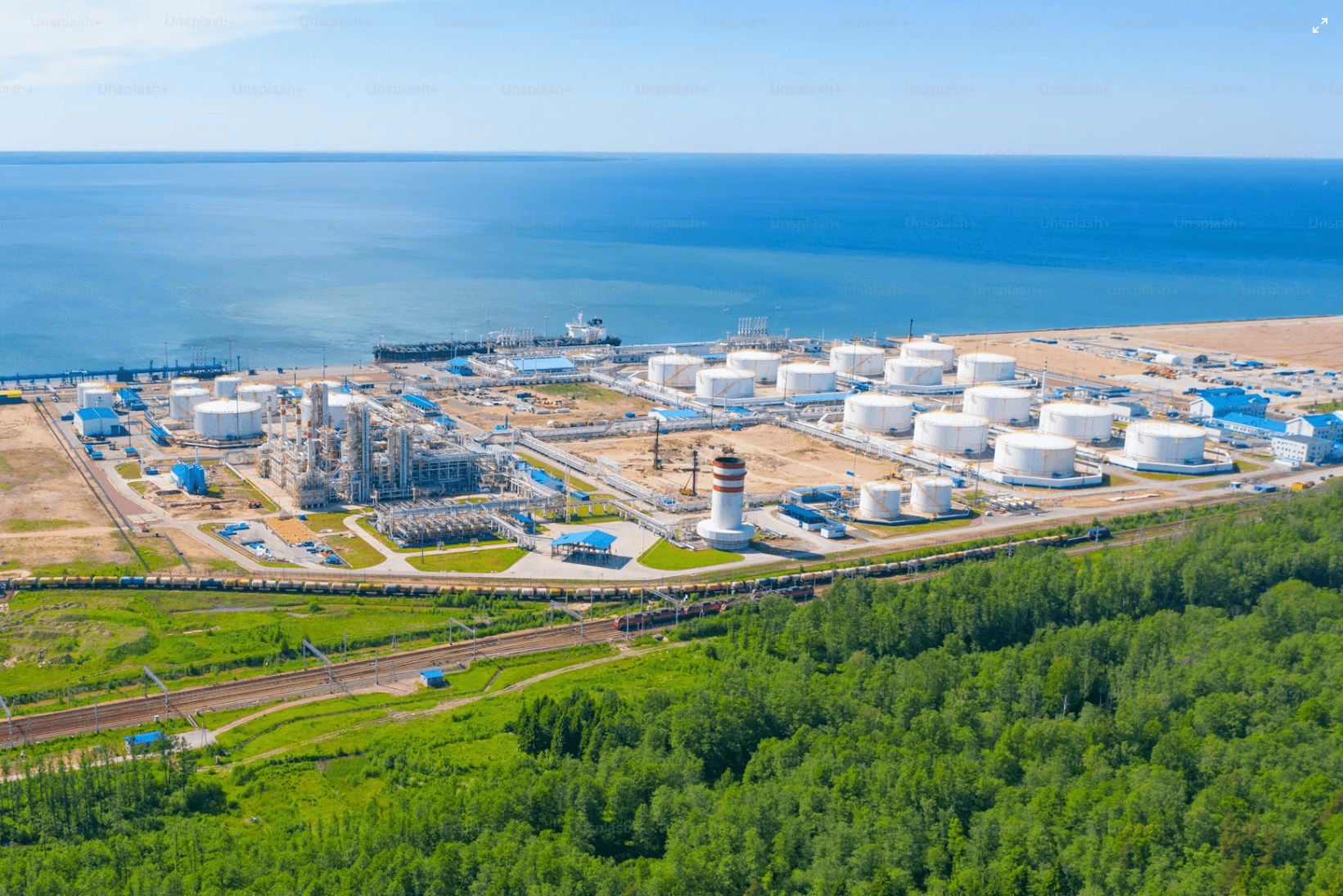

Our Market Solutions

A scalable, low-emission process that delivers reliable fuel quality, long-term environmental benefits, and durable economic performance.

Our Process

Our Process

Curve Energy’s patented green chemistry desulfurization process upgrades Heavy Fuel Oil (HSFO) to Very Low Sulfur Fuel Oil (VLSFO) under near-ambient conditions by removing sulfur at the molecular level.

The hydrogen-free process produces IMO-compliant fuel with a low carbon footprint. It is known that the treatment also removes nitrogen- and vanadium-containing compounds.

Curve Energy’s patented green chemistry desulfurization process upgrades Heavy Fuel Oil (HSFO) to Very Low Sulfur Fuel Oil (VLSFO) under near-ambient conditions by removing sulfur at the molecular level.

The hydrogen-free process produces IMO-compliant fuel with a low carbon footprint. It is known that the treatment also removes nitrogen- and vanadium-

containing compounds.

Hydrogen-Free Process

The Curve Advantage

Low-Emission, Compliant, & Future-Proof Process

A near-ambient, hydrogen-free process that delivers deep sulfur removal without the emissions, infrastructure, or regulatory risks of conventional refinery-based systems. Designed from the ground up for long-term compliance as marine fuel standards tighten.

Low-Emission, Compliant, & Future-Proof Process

A near-ambient, hydrogen-free process that delivers deep sulfur removal without the emissions, infrastructure, or regulatory risks of conventional refinery-based systems. Designed from the ground up for long-term compliance as marine fuel standards tighten.

Cleaner, High-Quality, & Engine-Friendly Fuel

True molecular-level sulfur extraction delivers stable, predictable fuel quality with improved combustion performance. The result is cleaner-burning fuel that protects engines, reduces maintenance, and ensures consistent compliance without blending or additives.

Cleaner, High-Quality, & Engine-Friendly Fuel

True molecular-level sulfur extraction delivers stable, predictable fuel quality with improved combustion performance. The result is cleaner-burning fuel that protects engines, reduces maintenance, and ensures consistent compliance without blending or additives.

Scalable & Cost-Effective Deployment Model

A modular, tank-to-tank deployment model enables rapid scaling across ports, terminals, and refineries with minimal capital investment. As throughput increases, treatment costs decline—supporting durable economics and global rollout.

Scalable & Cost-Effective Deployment Model

A modular, tank-to-tank deployment model enables rapid scaling across ports, terminals, and refineries with minimal capital investment. As throughput increases, treatment costs decline—supporting durable economics and global rollout.

Low-Emission, Compliant, & Future-Proof Process

A near-ambient, hydrogen-free process that delivers deep sulfur removal without the emissions, infrastructure, or regulatory risks of conventional refinery-based systems. Designed from the ground up for long-term compliance as marine fuel standards tighten.

Scalable & Cost-Effective Deployment Model

A modular, tank-to-tank deployment model enables rapid scaling across ports, terminals, and refineries with minimal capital investment. As throughput increases, treatment costs decline—supporting durable economics and global rollout.

Cleaner, High-Quality, & Engine-Friendly Fuel

True molecular-level sulfur extraction delivers stable, predictable fuel quality with improved combustion performance. The result is cleaner-burning fuel that protects engines, reduces maintenance, and ensures consistent compliance without blending or additives.

Market Validation & Traction

Market Validation & Traction

Proven Technology

Extensive R&D and testing confirm that Curve’s green-chemistry process effectively removes sulfur and is known to also reduce nitrogenand vanadium-containing compounds under near-ambient operating conditions.

Commercial Rollout

The first plant is planned for Singapore, the world’s largest bunkering hub, with active discussions underway with major ports, refineries, and industry partners to support broader deployment.

Global Patent Coverage

The process is secured by an international PCT filing, with patents issued in the United States, Malaysia, and Saudi Arabia, and national phase applications advancing across the Americas, Europe, the Middle East, and Asia, supporting broad market access and IP protection.

Strategic Expansion

The modular Tank-to-Tank system enables rapid deployment at key maritime and refining locations across the Middle East, Europe, Asia, and the Americas, supporting expansion into global markets.

Proven Technology

Extensive R&D and testing confirm that Curve’s green-chemistry process effectively removes sulfur and is known to also reduce nitrogenand vanadium-containing compounds under near-ambient operating conditions.

Global Patent Coverage

The process is secured by an international PCT filing, with patents issued in the United States, Malaysia, and Saudi Arabia, and national phase applications advancing across the Americas, Europe, the Middle East, and Asia, supporting broad market access and IP protection.

Commercial Rollout

The first plant is planned for Singapore, the world’s largest bunkering hub, with active discussions underway with major ports, refineries, and industry partners to support broader deployment.

Strategic Expansion

The modular Tank-to-Tank system enables rapid deployment at key maritime and refining locations across the Middle East, Europe, Asia, and the Americas, supporting expansion into global markets.

Proven Technology

Extensive R&D and testing confirm that Curve’s green-chemistry process effectively removes sulfur and is known to also reduce nitrogenand vanadium-containing compounds under near-ambient operating conditions.

Commercial Rollout

The first plant is planned for Singapore, the world’s largest bunkering hub, with active discussions underway with major ports, refineries, and industry partners to support broader deployment.

Global Patent Coverage

The process is secured by an international PCT filing, with patents issued in the United States, Malaysia, and Saudi Arabia, and national phase applications advancing across the Americas, Europe, the Middle East, and Asia, supporting broad market access and IP protection.

Strategic Expansion

The modular Tank-to-Tank system enables rapid deployment at key maritime and refining locations across the Middle East, Europe, Asia, and the Americas, supporting expansion into global markets.

Traditional Strategies

Where Existing Methods Fall Short

Hydrogen Desulfurization

SMR-based hydrogen production remains poorly suited for marine applications due to high emissions, capital intensity, and limited deployment flexibility. Its reliance on extreme operating conditions drives both cost and carbon exposure while constraining scalability beyond refinery environments.

Hydrogen Desulfurization

SMR-based hydrogen production remains poorly suited for marine applications due to high emissions, capital intensity, and limited deployment flexibility. Its reliance on extreme operating conditions drives both cost and carbon exposure while constraining scalability beyond refinery environments.

Blended Fuels

Fuel blending offers only a temporary compliance workaround by diluting sulfur rather than eliminating it, leaving operators exposed as regulations tighten. Operational instability and reliance on premium inputs further undermine its viability as a long-term solution.

Blended Fuels

Fuel blending offers only a temporary compliance workaround by diluting sulfur rather than eliminating it, leaving operators exposed as regulations tighten. Operational instability and reliance on premium inputs further undermine its viability as a long-term solution.

Scrubbers

Scrubber systems reduce air emissions but transfer pollution to the marine environment while introducing growing regulatory, operational, and infrastructure challenges. As bans expand and waste handling remains unresolved, long-term scalability is increasingly uncertain.

Scrubbers

Scrubber systems reduce air emissions but transfer pollution to the marine environment while introducing growing regulatory, operational, and infrastructure challenges. As bans expand and waste handling remains unresolved, long-term scalability is increasingly uncertain.

Hydrogen Desulfurization

SMR-based hydrogen production remains poorly suited for marine applications due to high emissions, capital intensity, and limited deployment flexibility. Its reliance on extreme operating conditions drives both cost and carbon exposure while constraining scalability beyond refinery environments.

Scrubbers

Scrubber systems reduce air emissions but transfer pollution to the marine environment while introducing growing regulatory, operational, and infrastructure challenges. As bans expand and waste handling remains unresolved, long-term scalability is increasingly uncertain.

Blended Fuels

Fuel blending offers only a temporary compliance workaround by diluting sulfur rather than eliminating it, leaving operators exposed as regulations tighten. Operational instability and reliance on premium inputs further undermine its viability as a long-term solution.